| MOQ: | 500KG |

| Price: | 3.15 -5.25USD/KG |

| Standard Packaging: | Wooden Pallet |

| Delivery Period: | 7 Days |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 80000KGS |

| Product Classification | Stainless Steel Round Bar |

| Dia | 4-30mm Cold Drawn |

| 30-300 Hot Rolled | |

| Technique | Cold Rolled Hot Rolled |

| Length | 2000mm,2440mm,3000mm,5800mm,6000mm,etc |

| Surface | Black Bright |

| Quality test | we can offer MTC(mill test certificate) |

| Grade | 304.304L.321.316.316L.316H.316Ti.316LN.317.317L.904L.309S.310S.C-276.C-22.C-2000.C-4.B-2.B-3.G-3.G-30.2550.2507.2205.2520.2101.2304.904L.724L.725LN.etc |

| Use | Widely used Light industry, heavy industry, daily necessities and decoration industries |

| Provenance | Jiangsu, China |

| Trademark | TSING SHAN STEEL |

| Product Description | Cold rolled steel is produced through cold rolling. Cold rolling is the process of further reducing the No.1 steel plate to the target thickness at room temperature. Compared with hot-rolled steel plates, cold-rolled steel plates have a more precise thickness, a smooth and beautiful surface, and various superior mechanical properties, especially processing performance. Mainly used in construction, light industry, automobiles, agriculture, animal husbandry, fisheries, and commerce. Among them, the construction industry is mainly used for manufacturing anti-corrosion industrial and civil building roof panels, roof grilles, etc. Light industry uses them to manufacture household appliance shells, civil chimneys, kitchen utensils, etc. The automotive industry is mainly used for manufacturing corrosion-resistant components of automobiles. Agriculture, animal husbandry, and fisheries are mainly used for grain storage and transportation, as well as equipment for freezing and processing meat and aquatic products, while commerce is mainly used for material storage. Transportation, packaging, etc |

Alloy 347 is frequently used for the fabrication of equipment, which must be placed in service under severe corrosive conditions, and is also common to the petroleum refining industries. Applications that consistently used Alloy 347 include:

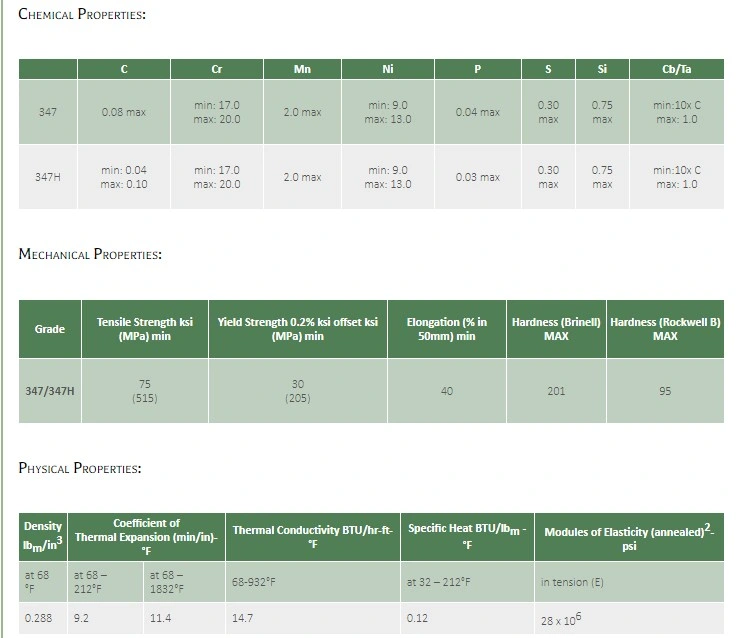

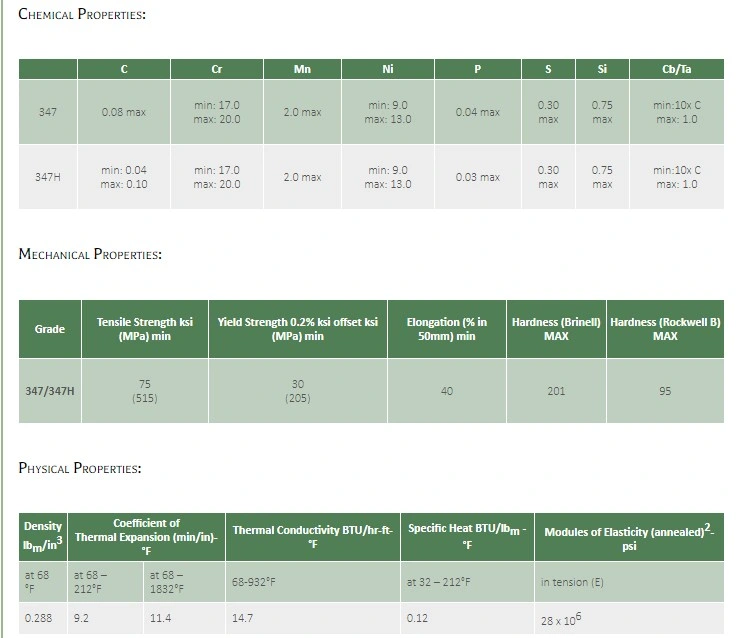

Chemical property & mechanical properties:

Products Show

![]()

![]()

![]()

![]()

![]()

1. When can I get the quotation?

We usually quote 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your e-mail so that we will regard your inquiry priority.

2. How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality counter display.

If you need the samples, we will charge for the sample Express fee. But the cost can be refundable after order confirmation when your quantity of the order is more about the MOQ.

3. Can you do the design for us?

Yes. We have a professional team having rich experience in design and manufacturing. Just tell us your idea and we will help to carry out your ideas. It does not matter if you do not have someone to complete files. Send us high resolution images, your logo and text and tell us how you would like to arrange them. We will send you finished files for confirmation.

4. How long can I expect to get the samples?

After you pay the sample charge and send us confirmation files, the samples will be ready for delivery in 3-7 days. You can use your own express account or prepay us if you do not have an account.

5. What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. The lead time of MOQ is about 10 to 15 days. Generally speaking, we suggest that you start inquiry two months before the date you would like to get the product at your country.

6. What is your terms of delivery?

We accept EXW, FOB, C&F and CIF, etc. You can choose the one which is the most convenient or cost effective for you.

| MOQ: | 500KG |

| Price: | 3.15 -5.25USD/KG |

| Standard Packaging: | Wooden Pallet |

| Delivery Period: | 7 Days |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 80000KGS |

| Product Classification | Stainless Steel Round Bar |

| Dia | 4-30mm Cold Drawn |

| 30-300 Hot Rolled | |

| Technique | Cold Rolled Hot Rolled |

| Length | 2000mm,2440mm,3000mm,5800mm,6000mm,etc |

| Surface | Black Bright |

| Quality test | we can offer MTC(mill test certificate) |

| Grade | 304.304L.321.316.316L.316H.316Ti.316LN.317.317L.904L.309S.310S.C-276.C-22.C-2000.C-4.B-2.B-3.G-3.G-30.2550.2507.2205.2520.2101.2304.904L.724L.725LN.etc |

| Use | Widely used Light industry, heavy industry, daily necessities and decoration industries |

| Provenance | Jiangsu, China |

| Trademark | TSING SHAN STEEL |

| Product Description | Cold rolled steel is produced through cold rolling. Cold rolling is the process of further reducing the No.1 steel plate to the target thickness at room temperature. Compared with hot-rolled steel plates, cold-rolled steel plates have a more precise thickness, a smooth and beautiful surface, and various superior mechanical properties, especially processing performance. Mainly used in construction, light industry, automobiles, agriculture, animal husbandry, fisheries, and commerce. Among them, the construction industry is mainly used for manufacturing anti-corrosion industrial and civil building roof panels, roof grilles, etc. Light industry uses them to manufacture household appliance shells, civil chimneys, kitchen utensils, etc. The automotive industry is mainly used for manufacturing corrosion-resistant components of automobiles. Agriculture, animal husbandry, and fisheries are mainly used for grain storage and transportation, as well as equipment for freezing and processing meat and aquatic products, while commerce is mainly used for material storage. Transportation, packaging, etc |

Alloy 347 is frequently used for the fabrication of equipment, which must be placed in service under severe corrosive conditions, and is also common to the petroleum refining industries. Applications that consistently used Alloy 347 include:

Chemical property & mechanical properties:

Products Show

![]()

![]()

![]()

![]()

![]()

1. When can I get the quotation?

We usually quote 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your e-mail so that we will regard your inquiry priority.

2. How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality counter display.

If you need the samples, we will charge for the sample Express fee. But the cost can be refundable after order confirmation when your quantity of the order is more about the MOQ.

3. Can you do the design for us?

Yes. We have a professional team having rich experience in design and manufacturing. Just tell us your idea and we will help to carry out your ideas. It does not matter if you do not have someone to complete files. Send us high resolution images, your logo and text and tell us how you would like to arrange them. We will send you finished files for confirmation.

4. How long can I expect to get the samples?

After you pay the sample charge and send us confirmation files, the samples will be ready for delivery in 3-7 days. You can use your own express account or prepay us if you do not have an account.

5. What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. The lead time of MOQ is about 10 to 15 days. Generally speaking, we suggest that you start inquiry two months before the date you would like to get the product at your country.

6. What is your terms of delivery?

We accept EXW, FOB, C&F and CIF, etc. You can choose the one which is the most convenient or cost effective for you.