| MOQ: | 100KGS |

| Price: | 40 USD/KG |

| Standard Packaging: | Wooden Box |

| Delivery Period: | 7 Days |

| Payment Method: | L/C, Western Union, T/T |

| Supply Capacity: | 80000KGS |

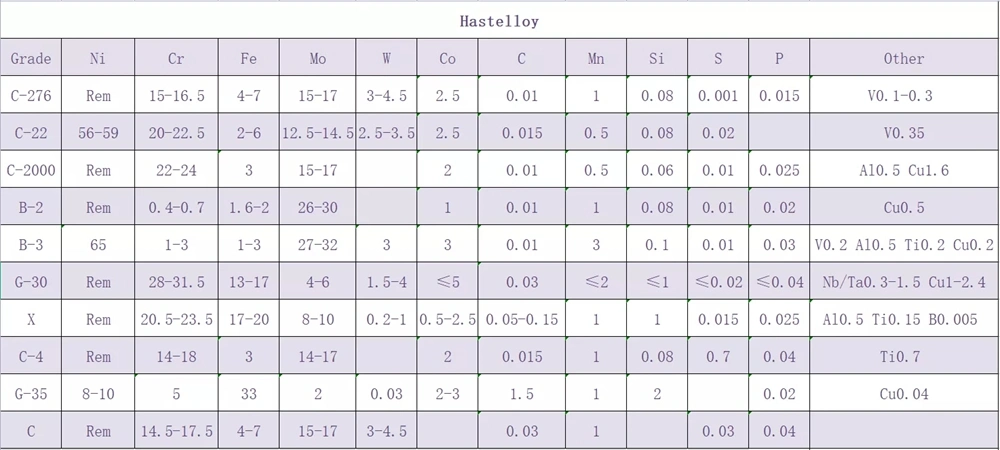

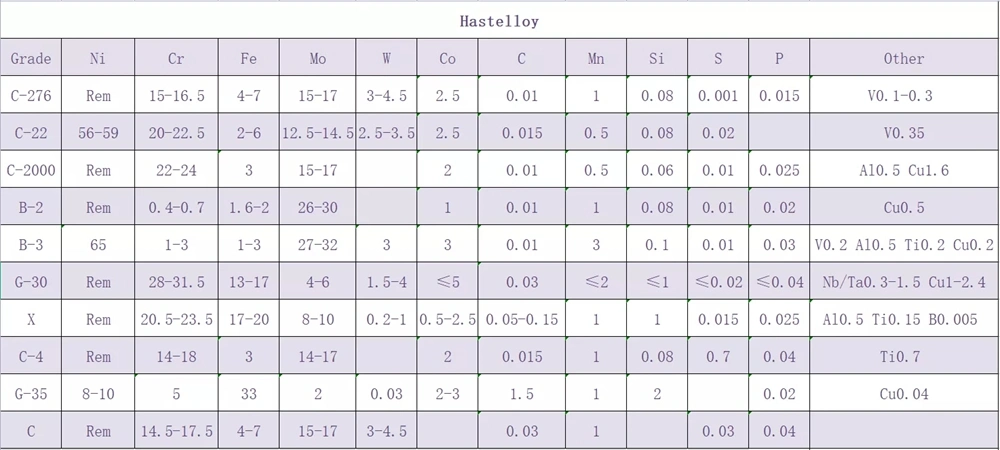

Hastelloy is a nickel-based corrosion-resistant alloy, which is mainly divided into two categories: nickel-chromium alloy and nickel-chromium-molybdenum alloy. Hastelloy has good corrosion resistance and thermal stability, and is mostly used in aviation, chemical fields, etc.

| Material | Inconel,Hastelloy,Monel,Incoloy,GH,Precision alloy,Stainless steel | |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc | |

| Shape | Sheet ,Coil, Bar,Pipe,Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square | |

| Surface | Mirror,Brushed,Mil Finished,Polished etc | |

| Material Grade | Inconel | Inconel600(N06600 GH3600), Inconel601(N06601 GH3600), Inconel625(N06625 GH3625), InconelX-750(N07750 GH4145), Inconel 718(N07718 GH4169), Inconel690 |

| Hastelloy | Hastelloy B-2,Hastelloy C,Hastelloy C-267(N10276),Hastelloy C-4, Hastelloy C-22(N06022),Hastelloy G30(N06030) |

|

| Monel | Monel 400(N04400),Monel K500(N05500) | |

| Incoloy | Incoloy A-286(GH2132 N662),Incoloy800 800H 800HT,Incoloy725, Incoloy825,Incoloy925,Incoloy926(N08926 1.4529) |

|

| GH | GH2132(N66286 A286 Gr6),GH3625(Inconel625 UNS N0), GH4169(Inconel718 UNS N0),GH3030,GH3039,GH4033,GH3128 |

|

| Precision alloy | 4J36,4J29,1J79 | |

| Stainless steel | Alloy 20(N08020),904L(N08904),254SMo(F44 S31254) | |

| Specification | Sheet | Thickness 0.8-36mm; Width 650-2000mm; Length 800-4500mm |

| Strip | 0.05*5.0-5.0*250mm | |

| Pipe | φ 6-273mm; Thickness 1-30mm; Length 1000-8000mm | |

| Bar | φ4-50mm; Length 2000-5000mm | |

| Wire | 0.01-10mm | |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc |

|

| Type | Chemical composition of code |

Chemical composition.% | ||||||||

| C | Mn | Fe | Si | Cu | Ni | Cr | Mo | W | ||

| SNi6276 | NiCr15Mo16Fe6W4 | ≤0.02 | ≤1.0 | 4.0-7.0 | ≤0.08 | ≤0.5 | ≥50.0 | 14.5-16.5 | 15.0-17.0 | 3.0-4.5 |

| Grade | % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S |

| C-276 | Min | Bal. | 14.5 | 15 | 4 | 3 | |||||||

| Max | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.35 | 0.04 | 0.03 |

| Process | Diameter | Voltage | Amperage | Gas |

| TIG | .045" (1.2mm) | 13-16 | 80-110 | 100% Argon |

| 1/16" (1.6mm) | 14-18 | 90-130 | 100% Argon | |

| 3/32" (2.4mm) | 15-20 | 120-175 | 100% Argon | |

| 1/8" (3.2mm) | 15-20 | 150-220 | 100% Argon | |

| MIG | .045" (1.2mm) | 28-32 | 180-220 | 75% Argon + 25% Helium |

| 1/16" (1.6mm) | 29-33 | 200-250 | 75% Argon + 25% Helium | |

| SAW | 3/32" (2.4mm) | 28-30 | 275-350 | Suitable Flux may be used |

| 1/8" (3.2mm) | 29-32 | 350-450 | Suitable Flux may be used | |

| 5/32" (4.0mm) | 30-33 | 400-550 | Suitable Flux may be used |

|

Hastelloy

|

Density

g/cm3

|

Melting point

ºC

|

Elongation A5 %

|

Tensile Strength

Rm N/mm2

|

Yield Strength

RP0.2N/mm2

|

|

C-276

|

8.9

|

1325-1370ºC

|

62

|

758

|

363

|

|

C-22

|

8.9

|

1325-1370 ºC

|

40

|

690

|

283

|

|

C-2000

|

8.5

|

1399ºC 2550°F

|

45

|

690

|

283

|

|

B-2

|

9.2

|

1330-1380ºC

|

40

|

745

|

325

|

|

B-3

|

9.22

|

1370-1418ºC

|

40

|

760

|

350

|

|

G-30

|

8.22

|

1399ºC 2550°F

|

62

|

524

|

200

|

|

X

|

8.3

|

1260-1355ºC

|

30

|

690

|

/

|

|

C-4

|

8.64

|

399°C 2550°F

|

40

|

690

|

280

|

|

G-35

|

8.22

|

1370-1400ºC

|

/

|

/

|

/

|

|

C

|

8.94

|

1330-1380 ºC

|

40

|

690

|

310

|

![]()

![]()

![]()

| MOQ: | 100KGS |

| Price: | 40 USD/KG |

| Standard Packaging: | Wooden Box |

| Delivery Period: | 7 Days |

| Payment Method: | L/C, Western Union, T/T |

| Supply Capacity: | 80000KGS |

Hastelloy is a nickel-based corrosion-resistant alloy, which is mainly divided into two categories: nickel-chromium alloy and nickel-chromium-molybdenum alloy. Hastelloy has good corrosion resistance and thermal stability, and is mostly used in aviation, chemical fields, etc.

| Material | Inconel,Hastelloy,Monel,Incoloy,GH,Precision alloy,Stainless steel | |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc | |

| Shape | Sheet ,Coil, Bar,Pipe,Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square | |

| Surface | Mirror,Brushed,Mil Finished,Polished etc | |

| Material Grade | Inconel | Inconel600(N06600 GH3600), Inconel601(N06601 GH3600), Inconel625(N06625 GH3625), InconelX-750(N07750 GH4145), Inconel 718(N07718 GH4169), Inconel690 |

| Hastelloy | Hastelloy B-2,Hastelloy C,Hastelloy C-267(N10276),Hastelloy C-4, Hastelloy C-22(N06022),Hastelloy G30(N06030) |

|

| Monel | Monel 400(N04400),Monel K500(N05500) | |

| Incoloy | Incoloy A-286(GH2132 N662),Incoloy800 800H 800HT,Incoloy725, Incoloy825,Incoloy925,Incoloy926(N08926 1.4529) |

|

| GH | GH2132(N66286 A286 Gr6),GH3625(Inconel625 UNS N0), GH4169(Inconel718 UNS N0),GH3030,GH3039,GH4033,GH3128 |

|

| Precision alloy | 4J36,4J29,1J79 | |

| Stainless steel | Alloy 20(N08020),904L(N08904),254SMo(F44 S31254) | |

| Specification | Sheet | Thickness 0.8-36mm; Width 650-2000mm; Length 800-4500mm |

| Strip | 0.05*5.0-5.0*250mm | |

| Pipe | φ 6-273mm; Thickness 1-30mm; Length 1000-8000mm | |

| Bar | φ4-50mm; Length 2000-5000mm | |

| Wire | 0.01-10mm | |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc |

|

| Type | Chemical composition of code |

Chemical composition.% | ||||||||

| C | Mn | Fe | Si | Cu | Ni | Cr | Mo | W | ||

| SNi6276 | NiCr15Mo16Fe6W4 | ≤0.02 | ≤1.0 | 4.0-7.0 | ≤0.08 | ≤0.5 | ≥50.0 | 14.5-16.5 | 15.0-17.0 | 3.0-4.5 |

| Grade | % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S |

| C-276 | Min | Bal. | 14.5 | 15 | 4 | 3 | |||||||

| Max | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.35 | 0.04 | 0.03 |

| Process | Diameter | Voltage | Amperage | Gas |

| TIG | .045" (1.2mm) | 13-16 | 80-110 | 100% Argon |

| 1/16" (1.6mm) | 14-18 | 90-130 | 100% Argon | |

| 3/32" (2.4mm) | 15-20 | 120-175 | 100% Argon | |

| 1/8" (3.2mm) | 15-20 | 150-220 | 100% Argon | |

| MIG | .045" (1.2mm) | 28-32 | 180-220 | 75% Argon + 25% Helium |

| 1/16" (1.6mm) | 29-33 | 200-250 | 75% Argon + 25% Helium | |

| SAW | 3/32" (2.4mm) | 28-30 | 275-350 | Suitable Flux may be used |

| 1/8" (3.2mm) | 29-32 | 350-450 | Suitable Flux may be used | |

| 5/32" (4.0mm) | 30-33 | 400-550 | Suitable Flux may be used |

|

Hastelloy

|

Density

g/cm3

|

Melting point

ºC

|

Elongation A5 %

|

Tensile Strength

Rm N/mm2

|

Yield Strength

RP0.2N/mm2

|

|

C-276

|

8.9

|

1325-1370ºC

|

62

|

758

|

363

|

|

C-22

|

8.9

|

1325-1370 ºC

|

40

|

690

|

283

|

|

C-2000

|

8.5

|

1399ºC 2550°F

|

45

|

690

|

283

|

|

B-2

|

9.2

|

1330-1380ºC

|

40

|

745

|

325

|

|

B-3

|

9.22

|

1370-1418ºC

|

40

|

760

|

350

|

|

G-30

|

8.22

|

1399ºC 2550°F

|

62

|

524

|

200

|

|

X

|

8.3

|

1260-1355ºC

|

30

|

690

|

/

|

|

C-4

|

8.64

|

399°C 2550°F

|

40

|

690

|

280

|

|

G-35

|

8.22

|

1370-1400ºC

|

/

|

/

|

/

|

|

C

|

8.94

|

1330-1380 ºC

|

40

|

690

|

310

|

![]()

![]()

![]()