| MOQ: | 100KGS |

| Price: | 1.85 USD/KG |

| Standard Packaging: | Wooden Pallet |

| Delivery Period: | 7 Days |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 50000KGS |

| Item | Standard | Finish | Thick. (mm) |

Width (mm), Master Coil Sizes | Remark | |||||

| 1000 | 1219 | 1250 | 1500 | 1800 | 2000 | |||||

| 443 Stainless Steel Coil |

ASTM

JIS

GB

|

No.1 (1D) | 3.0~8.0 | ※ | ※ |

1.Cut length upto

12 meters

|

||||

| 2B, 2D | 0.4~3.0 | ※ | ※ | ※ | ||||||

1. With more than 20 years manufacturing experience, the biggest manufacturer in Jinan cold rolled stainless steel market.

2. With 100 million registered capital, more than 100,000 square meters area and more than 500 employees in our two factories.

3. Advanced equipment, including two of 18 roller cold rolling bright annealing machine and two of 20 roller's.

4. Stable and best quality with competitive price.

5. Prefect organization structure, good service.

|

Grade

|

201,202,304,304L,309, 309S,310S,316,316L,316Ti,317L,321,347H,409,409L,

410, 410S, 420(420J1, 420J2), 430, 436, 439, 441, 444, 446 etc. |

|

Thickness

|

0.3-14mm for coil, 0.3-80mm for plate

|

|

Width

|

1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet),

1800mm,2000mm or as your requirements |

|

Length

|

2000mm,2440mm(8feet),2500mm,3000mm,3048mm(10feet),

5800mm, 6000mm or as your requirements |

|

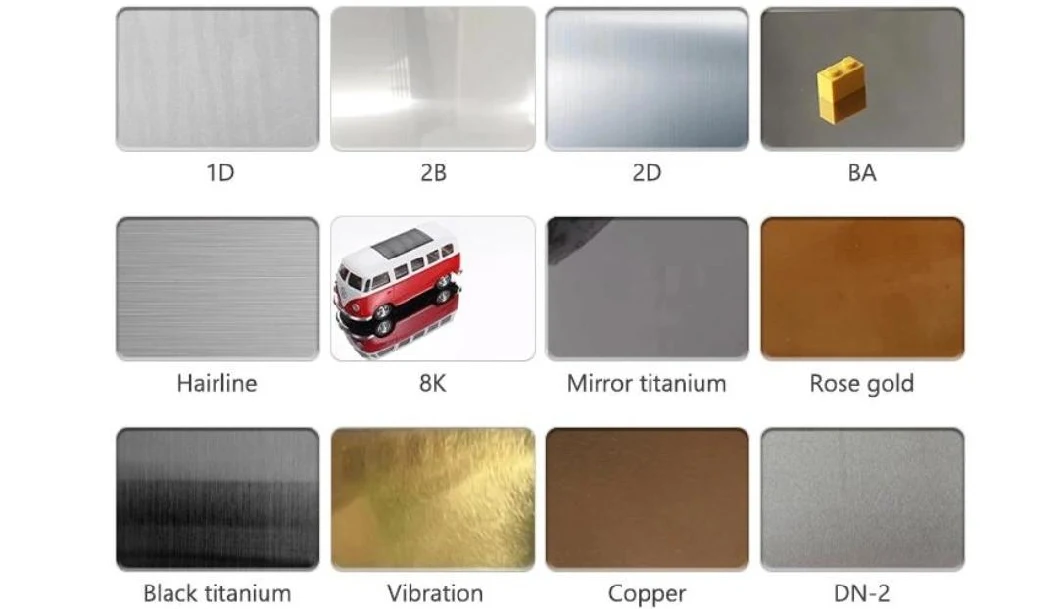

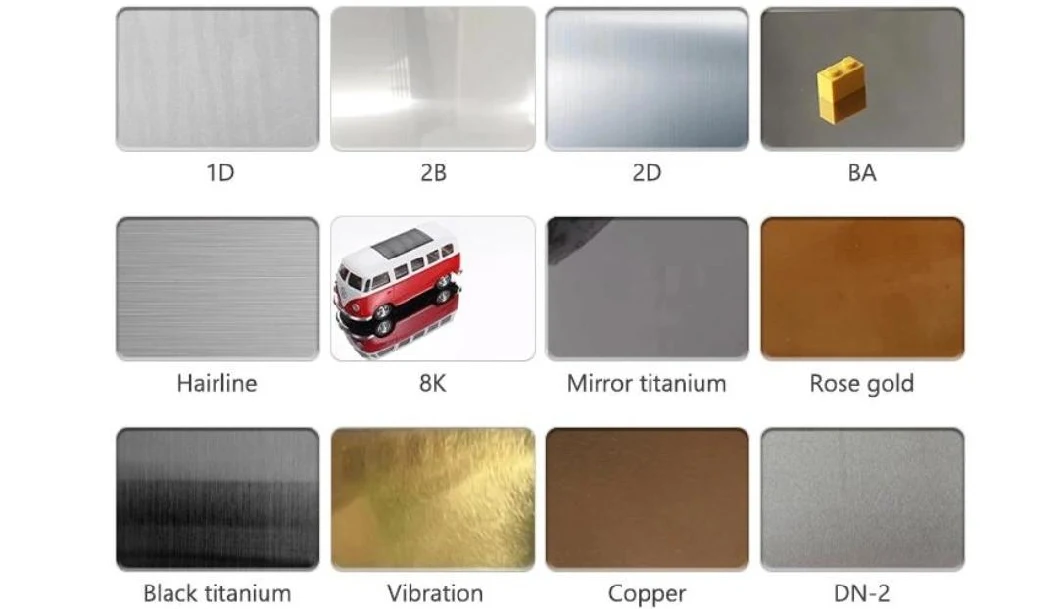

Surface

|

Common: 2B, 2D, HL(Hairline), BA(Bright annealed), No.4

Colored: Gold mirror, Sapphire mirror, Rose mirror, black mirror, bronze mirror; Gold brushed, Sapphire brushed, Rose brushed, black brushed etc. |

|

Packing & loaidng

|

Water proof paper+metal pallet+Angle bar protection+steel belt or as requirements.

The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM,23MTS 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM,27MTS 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM,27MTS |

|

Application

|

stainless steel coil used for architectural decoration, luxury doors, elevators decorating, metal tank shell, ship building,

decorated inside the train, as well as outdoor works, advertising nameplate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.. |

|

Advantage

|

Showing the splendor of your quality, wear-resistant as well, strong corrosion resistance and decorative effect, durable and

beautiful in good taste |

| Trade Terms | EXW, FOB, CFR, CIF |

| Delivery time | within 7 days |

| Payment terms | T/T,L/C or Other |

| Packaging | Standard seaworthy packing |

| Quantity | As your request |

Excellent corrosion resistance of 443 stainless steel. 443 stainless steel increases the content of chromium to 21%, and its corrosion resistance is as good as 304 stainless steel. secondly, titanium is added to play a stabilizing role, and it also retains good corrosion resistance after welding.

Price advantage and stability of 443 stainless steel. Because there is no need to add nickel to the chemical forming elements of 443 stainless steel, the price is cheaper than 304 stainless steel. And because there is no need to add nickel and molybdenum, the rise and fall of these two metals will not affect 443 stainless steel, and price fluctuations are rarely affected by exchange rate fluctuations.

443 stainless steel has the advantage of thermal conductivity. The thermal conductivity of 443 stainless steel is about 30% higher than that of 304 stainless steel, because it can save time and energy in the field of cooking equipment manufacturing, and because of its good magnetic conductivity, it can show the advantages of materials in induction cookers. The application effect of the material is better.

443 stainless steel has excellent resistance to atmospheric corrosion and is resistant to most organic and inorganic acids. Its high copper content improves the resistance of the alloy to reduce acid and oxidizing chloride environments. The alloy also exhibits good resistance to general and localized corrosion in chloride-rich environments.

443 stainless steel is not heat-treatable, but cold working can improve its mechanical properties. The hardening of the alloy can be achieved by hard-working, and it can be annealed at temperatures ranging from 816-900°C.

443 stainless steel has poor machinability compared to other stainless steel. The alloy has a high work hardening rate, making it challenging to machine. However, using sharp and rigid tools, slow speed, and sufficient lubrication can improve its machinability.

443 stainless steel can be welded using most conventional fusion welding methods. However, it is prone to cracking and distortion during welding, and careful control of the welding process is vital. Preheating is recommended before welding to minimize the risk of cracking, and the interpass temperature should be kept low.

In conclusion, 443 stainless steel is a cost-effective alternative to austenitic stainless steel. Its low carbon content, high copper content, and molybdenum give the alloy excellent resistance to chloride environments. Its good mechanical properties, corrosion resistance, and weldability make it an ideal material for various applications, including automotive exhaust systems, heat exchangers, and chemical tanks. Since the alloy has poor machinability, it is crucial to use sharp and rigid tools, slow speed, and sufficient lubrication when machining. If you are looking for a durable material that can withstand corrosive environments and high mechanical loads, 443 stainless steel is the way to go.

![]()

![]()

![]()

| MOQ: | 100KGS |

| Price: | 1.85 USD/KG |

| Standard Packaging: | Wooden Pallet |

| Delivery Period: | 7 Days |

| Payment Method: | L/C, T/T |

| Supply Capacity: | 50000KGS |

| Item | Standard | Finish | Thick. (mm) |

Width (mm), Master Coil Sizes | Remark | |||||

| 1000 | 1219 | 1250 | 1500 | 1800 | 2000 | |||||

| 443 Stainless Steel Coil |

ASTM

JIS

GB

|

No.1 (1D) | 3.0~8.0 | ※ | ※ |

1.Cut length upto

12 meters

|

||||

| 2B, 2D | 0.4~3.0 | ※ | ※ | ※ | ||||||

1. With more than 20 years manufacturing experience, the biggest manufacturer in Jinan cold rolled stainless steel market.

2. With 100 million registered capital, more than 100,000 square meters area and more than 500 employees in our two factories.

3. Advanced equipment, including two of 18 roller cold rolling bright annealing machine and two of 20 roller's.

4. Stable and best quality with competitive price.

5. Prefect organization structure, good service.

|

Grade

|

201,202,304,304L,309, 309S,310S,316,316L,316Ti,317L,321,347H,409,409L,

410, 410S, 420(420J1, 420J2), 430, 436, 439, 441, 444, 446 etc. |

|

Thickness

|

0.3-14mm for coil, 0.3-80mm for plate

|

|

Width

|

1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet),

1800mm,2000mm or as your requirements |

|

Length

|

2000mm,2440mm(8feet),2500mm,3000mm,3048mm(10feet),

5800mm, 6000mm or as your requirements |

|

Surface

|

Common: 2B, 2D, HL(Hairline), BA(Bright annealed), No.4

Colored: Gold mirror, Sapphire mirror, Rose mirror, black mirror, bronze mirror; Gold brushed, Sapphire brushed, Rose brushed, black brushed etc. |

|

Packing & loaidng

|

Water proof paper+metal pallet+Angle bar protection+steel belt or as requirements.

The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM,23MTS 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM,27MTS 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM,27MTS |

|

Application

|

stainless steel coil used for architectural decoration, luxury doors, elevators decorating, metal tank shell, ship building,

decorated inside the train, as well as outdoor works, advertising nameplate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.. |

|

Advantage

|

Showing the splendor of your quality, wear-resistant as well, strong corrosion resistance and decorative effect, durable and

beautiful in good taste |

| Trade Terms | EXW, FOB, CFR, CIF |

| Delivery time | within 7 days |

| Payment terms | T/T,L/C or Other |

| Packaging | Standard seaworthy packing |

| Quantity | As your request |

Excellent corrosion resistance of 443 stainless steel. 443 stainless steel increases the content of chromium to 21%, and its corrosion resistance is as good as 304 stainless steel. secondly, titanium is added to play a stabilizing role, and it also retains good corrosion resistance after welding.

Price advantage and stability of 443 stainless steel. Because there is no need to add nickel to the chemical forming elements of 443 stainless steel, the price is cheaper than 304 stainless steel. And because there is no need to add nickel and molybdenum, the rise and fall of these two metals will not affect 443 stainless steel, and price fluctuations are rarely affected by exchange rate fluctuations.

443 stainless steel has the advantage of thermal conductivity. The thermal conductivity of 443 stainless steel is about 30% higher than that of 304 stainless steel, because it can save time and energy in the field of cooking equipment manufacturing, and because of its good magnetic conductivity, it can show the advantages of materials in induction cookers. The application effect of the material is better.

443 stainless steel has excellent resistance to atmospheric corrosion and is resistant to most organic and inorganic acids. Its high copper content improves the resistance of the alloy to reduce acid and oxidizing chloride environments. The alloy also exhibits good resistance to general and localized corrosion in chloride-rich environments.

443 stainless steel is not heat-treatable, but cold working can improve its mechanical properties. The hardening of the alloy can be achieved by hard-working, and it can be annealed at temperatures ranging from 816-900°C.

443 stainless steel has poor machinability compared to other stainless steel. The alloy has a high work hardening rate, making it challenging to machine. However, using sharp and rigid tools, slow speed, and sufficient lubrication can improve its machinability.

443 stainless steel can be welded using most conventional fusion welding methods. However, it is prone to cracking and distortion during welding, and careful control of the welding process is vital. Preheating is recommended before welding to minimize the risk of cracking, and the interpass temperature should be kept low.

In conclusion, 443 stainless steel is a cost-effective alternative to austenitic stainless steel. Its low carbon content, high copper content, and molybdenum give the alloy excellent resistance to chloride environments. Its good mechanical properties, corrosion resistance, and weldability make it an ideal material for various applications, including automotive exhaust systems, heat exchangers, and chemical tanks. Since the alloy has poor machinability, it is crucial to use sharp and rigid tools, slow speed, and sufficient lubrication when machining. If you are looking for a durable material that can withstand corrosive environments and high mechanical loads, 443 stainless steel is the way to go.

![]()

![]()

![]()